Industrial submerged pumps play a vital role in a wide range of industries by improving efficiency a...

READ MORE

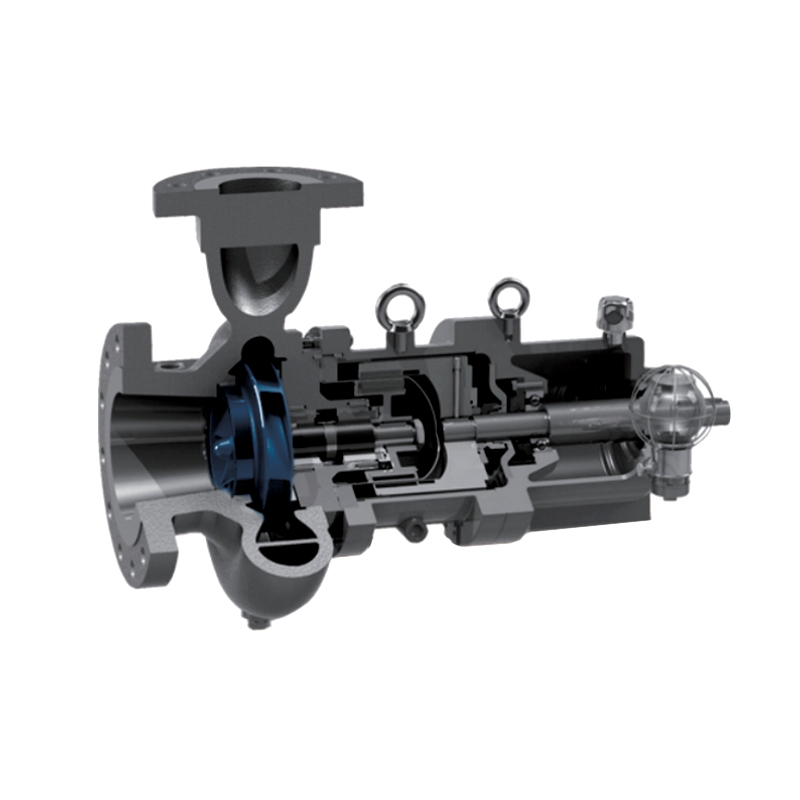

J12.5 Series Plunger Metering Pump

The J12.5 series plunger metering pump can transport high-viscosity media. The shaft seal is a packing seal, which has leakage and requires periodic adjustment of the packing. The packing and the plunger are a pair of wearing parts. The flow rate is within the range of 10% to 99.99%, the metering accuracy can reach 1%, the pressure can reach 80MPa, and the flow rate remains almost unchanged when the outlet pressure changes.

Product features:

• The plunger diameter can be made very small, but not too large, generally D=3-200mm;

• The discharge pressure range used by the plunger pump is relatively wide, and it is advisable to make it into a high-pressure pump;

• It can transport high-viscosity media, but it is not recommended to be used in the transportation of corrosive slurries and hazardous chemicals;

• There is no safety relief device. It is recommended to install a safety valve on the outlet pipeline of the pump;

• Simple structure, easy maintenance, and good cost performance;

• All plunger metering pumps can control the flow rate by adjusting the stroke length (installing a stroke regulator can achieve automatic adjustment) and changing the motor frequency, and remote control can be achieved.

Application range:

Transport of various corrosive solutions.

|

Flow |

28~380 L/H |

|

Stroke |

50mm |

|

Speed |

96~135 r/min |

|

Maximum pressure |

0.6~50 Mpa |

|

Plunger diameter |

12~110 mm |

|

Motor power |

2.2/4/5.5 KW |

SEND MESSAGE

Beloni (Jiangsu) Pump Manufacturing Co., Ltd

-

15+

Years Industry Experience

-

5000+

Factory Area

-

100+

Skillful Employees

-

30+

Product Category

The company is located at No. 18, Jinqiuzhu Road, Xinfeng, Shengci Town, Jingjiang City, in the lower reaches of the Yangtze River. Pump products include magnetic pumps, axial flow pumps, horizontal self-priming pumps, fluorine-lined centrifugal pumps, chemical desulfurization pumps, horizontal centrifugal pumps, bottom pumps, double-suction pumps, slurry pumps, rotor pumps, acid-resistant and wear-resistant pumps, chemical centrifugal pumps, wear-resistant and corrosion-resistant mortar pumps, seal-free fully automatic self-priming pumps, petrochemical process pumps, high-pressure oil pumps, vertical pipeline pumps, screw pumps and other series. Main products of metallurgical equipment: rare earth heat-resistant steel series, rare earth wear-resistant alloy steel series, bimetallic composite wear-resistant steel series, wear-resistant ceramic patch series, wear-resistant arc baffle series, medium-speed coal mill series, stabilizing roller, sinking roller, furnace roller, guide plate, step-type heating furnace series.

Beloni Pump Industry currently has 80 employees, including 12 professional and technical personnel, 6 inspectors, more than 100 sets of various metal cutting equipment, computer CAD-aided design, advanced detection and measurement devices, large-scale special processing equipment, large-scale lifting equipment, etc. The company has the production conditions from design, casting, machining, assembly, and testing. The company has successively obtained ISO9001 quality system certification, ISO14001 environmental management system certification, ISO45001 occupational health and safety management system, and multiple AAA certifications in the pump and valve industry.

At present, the company's products have been widely used in petrochemical, coal mines, power plants, steel mills, agricultural irrigation and drainage, industrial water supply and drainage, municipal construction, sewage treatment, and other industries.

As China J12.5 Series Plunger Metering Pump Suppliers and J12.5 Series Plunger Metering Pump Factory, the company provides industrial fluid safety delivery solutions for the global and domestic markets. It is a technology-based enterprise integrating chemical pump design, research and development, manufacturing, sales, and service. The company's quality-oriented and innovation-led business philosophy has been recognized by various users in the domestic and foreign markets; the company adheres to the core value of "making customers worry-free". The Mandeno Pump Industry continues to innovate and improve system service capabilities. It is committed to providing customers with safe, stable, and efficient pump products and services, exceeding customer expectations, and enhancing customer value!

-

-

In modern water management systems, how to ensure a continuous and stable water supply is the key to...

READ MORE -

Pressure Vessel Heat Exchanger have become one of the most popular and preferred choices in industri...

READ MORE -

The accuracy of an industrial metering diaphragm pump plays a crucial role in ensuring the efficienc...

READ MORE -

Industrial metering diaphragm pumps have earned a reputation for their precision, reliability, and e...

READ MORE

TOP

TOP

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG