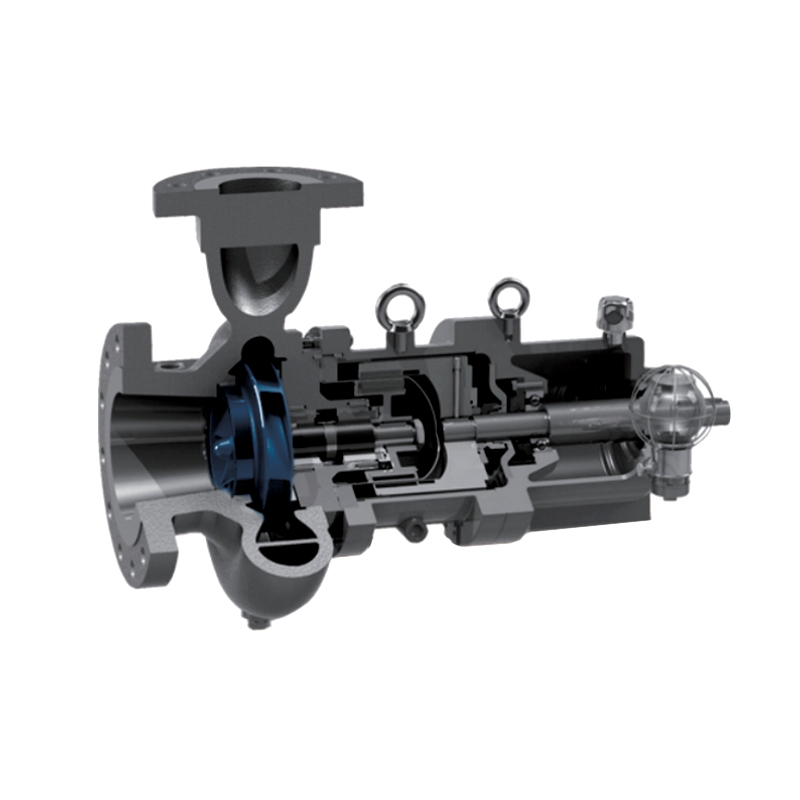

The industrial metering diaphragm pump achieves accurate metering and control of the flow rate by precisely controlling the reciprocating motion of the diaphragm and combining the precise switching of the suction and discharge valve group. This accuracy is particularly important in the chemical, pharmaceutical, food and other industries, because these industries often have strict requirements on the proportion and delivery volume of materials. The cooperation between the diaphragm pump and the suction and discharge valve group ensures that the amount of fluid delivered each time can meet the preset standard, thereby improving the stability of the production process and product quality.

The design and optimization of the suction and discharge valve group enables the diaphragm pump to reduce energy loss and improve the delivery efficiency when conveying fluids. During the operation of the pump, the suction and discharge valve group can quickly respond to the movement of the diaphragm to ensure that the fluid can flow smoothly during the suction and discharge process, avoiding energy waste caused by untimely opening or lax closing of the valve.

Industrial metering diaphragm pumps and suction and discharge valve groups are usually made of corrosion-resistant materials, such as stainless steel, polytetrafluoroethylene, etc. These materials can withstand the erosion of a variety of corrosive media, thereby extending the service life of the pump. The design of the suction and discharge valve group also takes into account wear resistance and corrosion resistance, so that the valve can still maintain good sealing performance and switching flexibility during long-term use. This design not only improves the reliability of the pump, but also reduces maintenance costs.

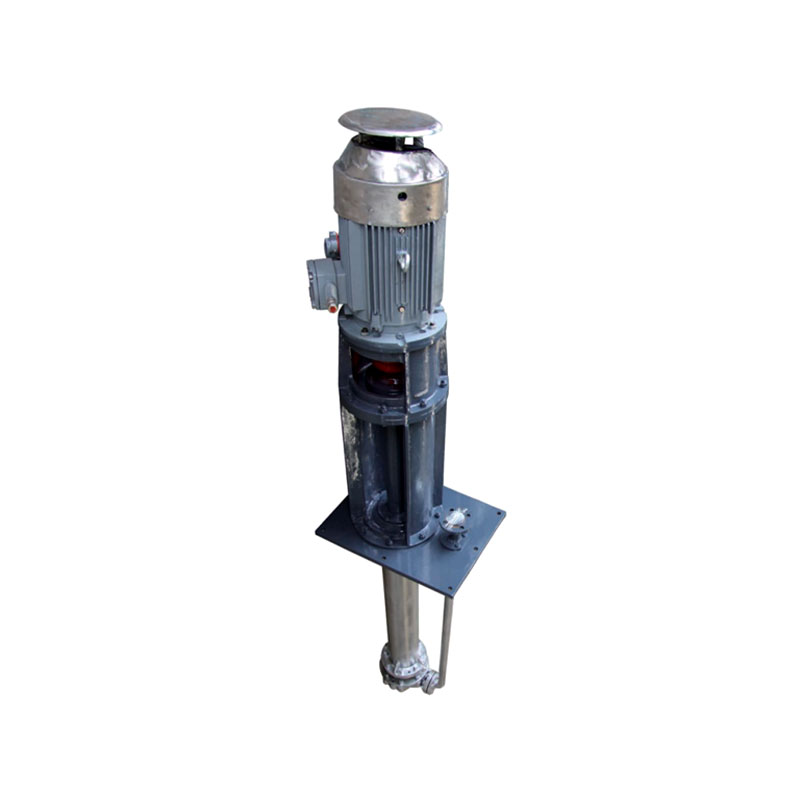

The combination of the diaphragm pump and the suction and discharge valve group enables the pump to adapt to a variety of different working environments and media conditions. Whether it is high viscosity, solid particles or corrosive media, the diaphragm pump can meet the delivery requirements by adjusting the movement parameters of the diaphragm and the structure of the suction and discharge valve group. The diaphragm pump also has a self-priming function, which can suck and deliver fluids without an external drainage device, further enhancing its adaptability and flexibility.

Recommended Products

Products provided by famous enterprises are deeply trusted by users.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP