When selecting and maintaining industrial pumps, the following important factors need to be considered:

Flow and head requirements: Determining the required pumping flow and head is the basis for selecting an appropriate industrial pump. Flow refers to the volume of liquid pumped per unit of time, and head refers to the vertical rise or pressure required for the liquid to move from the pump inlet to the outlet.

Media characteristics: It is very important to understand the characteristics of the pumped medium. This includes the viscosity of the liquid, temperature, degree of solid particles, chemical properties (such as corrosiveness, corrosiveness), flammability, etc. Different media characteristics may require the selection of pumps and seals of specific materials.

Process requirements: Consider the required process requirements, such as the need for specific pressures, temperature ranges, flow regulation, prevention of leakage, etc. These requirements will affect the selection and configuration of the pump.

Reliability and maintainability: Evaluate the reliability and maintainability of the pump, including the life, availability, and repair costs of the pump. Selecting a pump with good reliability and easy maintenance can reduce downtime and repair costs.

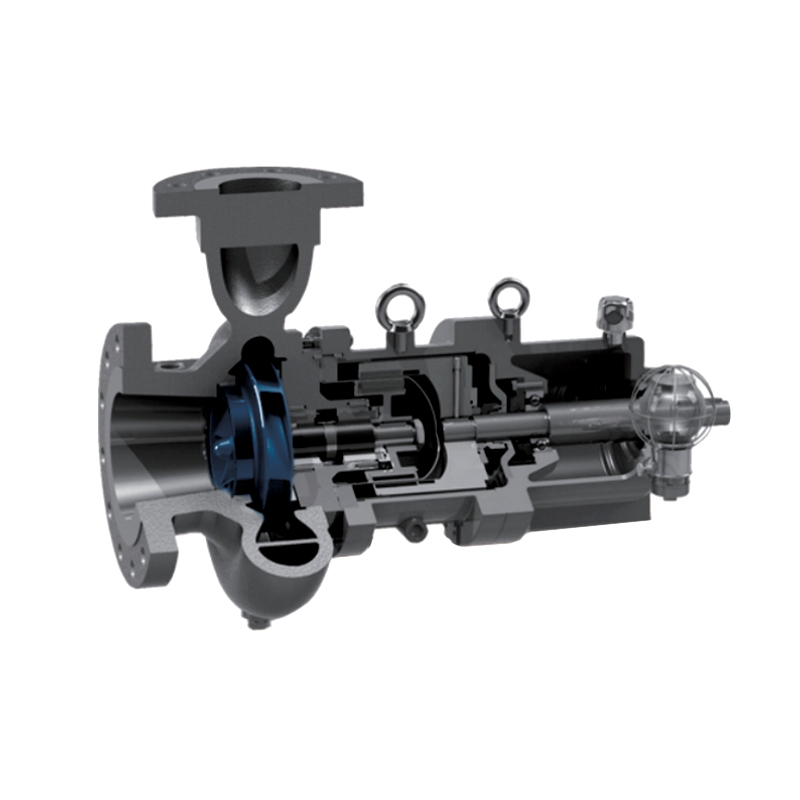

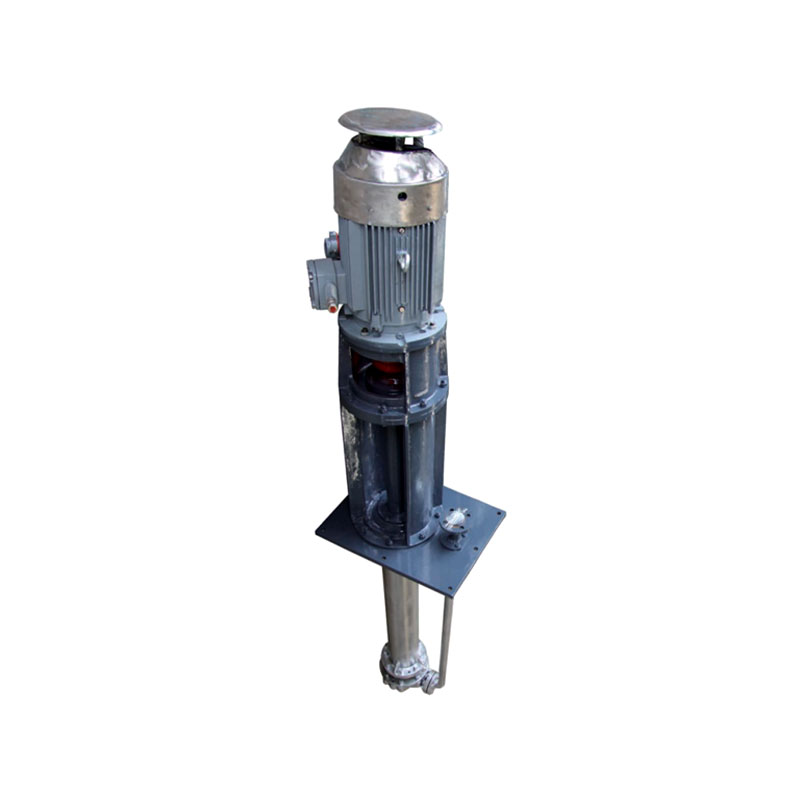

Pump types and working principles: Understand the different types of industrial pumps and their working principles to determine the pump suitable for a specific application. Different types of pumps are suitable for different process requirements and media characteristics.

Material selection: Select the appropriate pump material based on the chemical properties and characteristics of the pumped medium. Different materials may have different adaptability to corrosion, wear, and high-temperature resistance.

Energy efficiency and economy: Consider the energy efficiency and economy of the pump, including energy consumption, maintenance cost, and purchase cost. Choosing a pump with higher energy efficiency can reduce operating costs.

Pump supplier and technical support: Choose a reliable pump supplier and ensure that it provides good after-sales service and technical support. This is very important for installation, commissioning, maintenance, and troubleshooting.

When maintaining industrial pumps, it is necessary to regularly inspect and maintain the various parts of the pump, including seals, bearings, shaft seals, motors, etc. Keeping the pump clean, lubricated, and in the correct operating condition is also the key to maintenance. Follow the maintenance guidelines and recommendations provided by the manufacturer and perform regular maintenance and overhaul to ensure the normal operation and extended service life of the pump.

Please note that the above is only a general guide, and the specific selection and maintenance requirements may vary depending on different pump types, applications, and process requirements. It is recommended to consult a professional pump supplier or engineer in specific cases for more accurate and detailed advice.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP