The good heat shock resistance of ceramic lined composite pipes is attributed to the material properties of their ceramic lining layer. Ceramic materials, such as alumina and silicon nitride, typically have high melting points, high thermal conductivity, low thermal expansion coefficient, and good thermal stability. These characteristics enable ceramic materials to maintain stable physical and chemical properties at high temperatures, and are not prone to phase transition or decomposition.

Structural Design

The structural design of ceramic lined composite pipes is also an important guarantee for their thermal shock resistance. The pipeline usually consists of a three-layer structure consisting of a ceramic lining layer, a transition layer, and a steel pipe substrate. This structural design not only achieves a tight bond between ceramics and metals, but also effectively alleviates the thermal stress caused by the difference in thermal expansion coefficient between ceramics and metals through a transition layer. Specifically, the transition layer is usually made of materials with thermal expansion coefficients similar to ceramics and metals, such as nickel based alloy layers or gradient composite material layers that can provide buffering effects during temperature changes, reducing the concentration and transmission of thermal stress.

Thermal stress management

Thermal stress is a stress change caused by temperature differences inside and outside pipelines or changes in medium temperature. To reduce the impact of thermal stress on pipelines, the following measures can be taken:

Optimizing pipeline wall thickness: Reasonable wall thickness design can reduce thermal stress caused by temperature changes. Although thicker pipe walls can provide better mechanical strength, they can also increase the accumulation of thermal stress.

Using thermal compensation devices: Installing thermal compensation devices such as corrugated pipes, expansion joints, etc. in the pipeline system can provide a certain expansion space when the temperature changes, reducing the concentration and transmission of thermal stress.

Control the temperature of the medium: Try to maintain the stability of the medium temperature and avoid sudden temperature changes that may cause impact on the pipeline. In situations where the temperature of the medium changes significantly, measures such as preheating and slow cooling can be taken to reduce the impact of thermal stress.

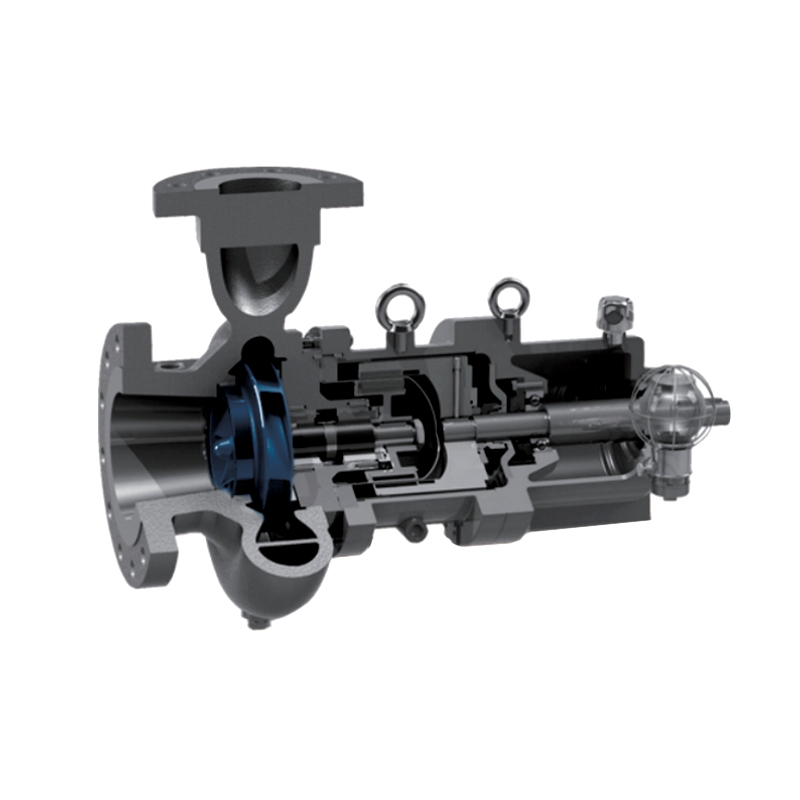

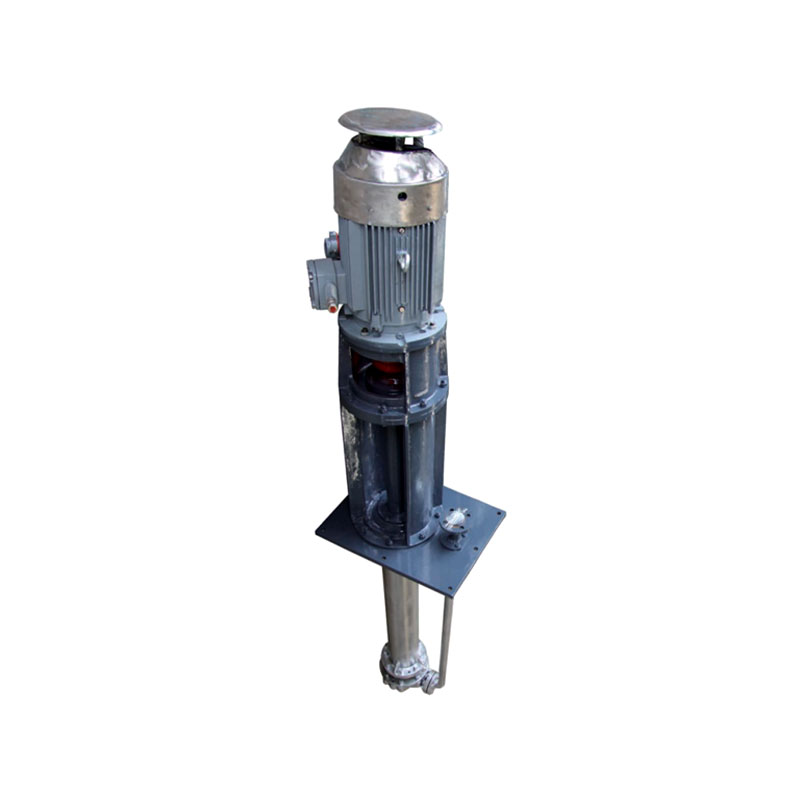

Recommended Products

Products provided by famous enterprises are deeply trusted by users.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP