Pressure vessels play a vital role in the chemical and petroleum industries. They are widely used, covering core functions from storage, transportation to reaction processes, and are directly related to the safety, efficiency and quality of production. Many operations in the chemical and petroleum industries need to be carried out under high temperature and high pressure, and pressure vessels are indispensable equipment in these special environments.

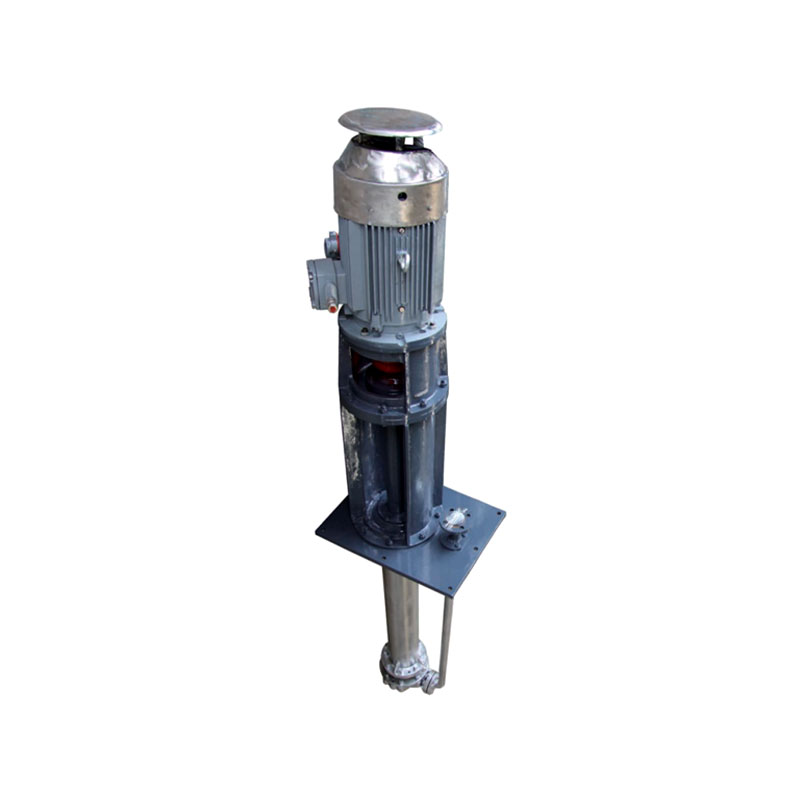

Pressure vessels play an important role in storage and transportation. In the chemical and petroleum industries, many raw materials and final products need to be stored under high pressure or low temperature. For example, liquefied natural gas, liquefied petroleum gas and certain chemical raw materials are gaseous or volatile at room temperature and pressure, and can only remain liquid under high pressure. Pressure vessels can effectively store these substances, prevent them from leaking or gasifying, and ensure their stability during transportation. Many hazardous chemicals are highly reactive or corrosive, and pressure vessels can provide a safe storage environment to avoid accidents that may be caused by chemicals during storage or transportation.

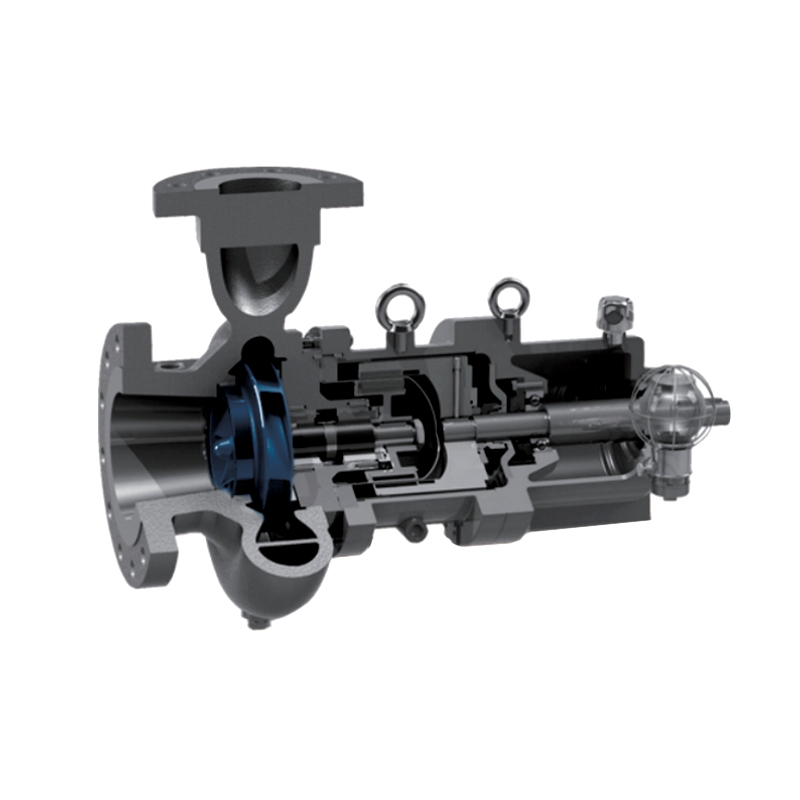

In the production process of the chemical and petroleum industries, many chemical reactions require high pressure conditions, especially in many links of petroleum refining and chemical synthesis. For example, the oil hydrocracking process needs to be carried out under high temperature and pressure, and only pressure vessels can provide the necessary environment for the reaction. These containers are not only containers for storing substances, but also serve as the core part of the reactor to support the occurrence of various high-pressure chemical reactions. Whether it is the cracking, polymerization reaction of oil, or the synthesis of other chemicals, pressure vessels provide a stable reaction environment to ensure that the reaction can proceed as expected, thereby improving production efficiency and product quality.

In addition to the role of the reactor, pressure vessels play an irreplaceable role in ensuring production safety. Many substances involved in the chemical and petroleum industries are extremely dangerous, such as flammable, explosive or toxic. Pressure vessels must be able to withstand the high pressure state of these dangerous substances to avoid serious accidents caused by container rupture or leakage. To ensure safety, pressure vessels need to strictly follow design and manufacturing standards, and need to be inspected and maintained regularly. Through regular inspections, potential hidden dangers of the equipment can be discovered in time, and necessary repair measures can be taken to ensure that the equipment operates in a safe state.

Pressure vessels can also significantly improve production efficiency. In many chemical reactions, the reaction rate is closely related to pressure. Appropriate high-pressure conditions can accelerate the reaction process, shorten the production cycle, and thus improve overall production efficiency. For example, in the oil refining process, the reaction speed under high pressure is significantly faster than that under normal pressure, which not only saves time, but also effectively reduces energy consumption and reduces production costs. Through the rational design and use of pressure vessels, enterprises can improve the overall efficiency of production while improving the quality of products.

The versatility of pressure vessels is also one of the important reasons for their widespread use in the chemical and petroleum industries. In addition to being reactors and storage vessels, pressure vessels can also be combined with other equipment as part of facilities such as coolers and heat exchangers. For example, in some chemical production processes, the reacted substances need to be cooled quickly to ensure stability. The design of pressure vessels can meet multiple needs such as reaction, storage and cooling at the same time, making the production process more efficient and coordinated. This versatility makes pressure vessels a key equipment in complex production lines, which can effectively integrate production systems and improve the stability of overall operations.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP