The vortex pump generates strong vortex motion through the high-speed rotating impeller, which can form strong turbulence and shear force in the liquid. This force enables fuller contact and mixing between fluid and solid particles, thereby improving the mixing effect. Compared with traditional mixers, vortex pumps can form a more uniform mixing system to ensure the consistency and stability of materials during the mixing process.

The vortex pump uses centrifugal force and shear force to work together to achieve uniform mixing of fluid and particles in a short time. This efficient mixing method greatly shortens mixing time and improves production efficiency. In industrial production, this means the mixing process can be completed faster, equipment occupancy time is reduced, and overall production capacity is increased.

The mixing principle of the vortex pump does not rely on the blade rotation of a traditional mixer, but generates turbulence and shear through the design of the guide blades and the high-speed rotation of the fluid. This mixing method consumes less energy than traditional mixers. In long-term use, it can significantly reduce the operating costs of enterprises and improve economic benefits.

The vortex pump is suitable for mixing a variety of fluids and granular materials. Its structural design and working principle enable it to handle materials of different viscosities and properties. This makes vortex pumps have broad application prospects in chemical, food, pharmaceutical and other industries. In addition, the vortex pump also has strong corrosion resistance and wear resistance, and can adapt to harsh working environments.

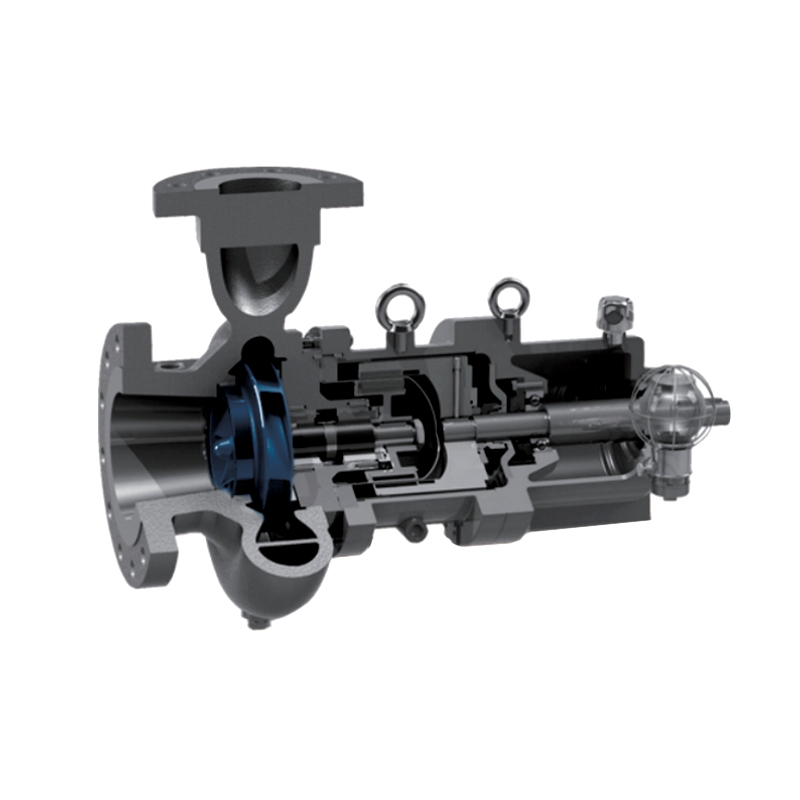

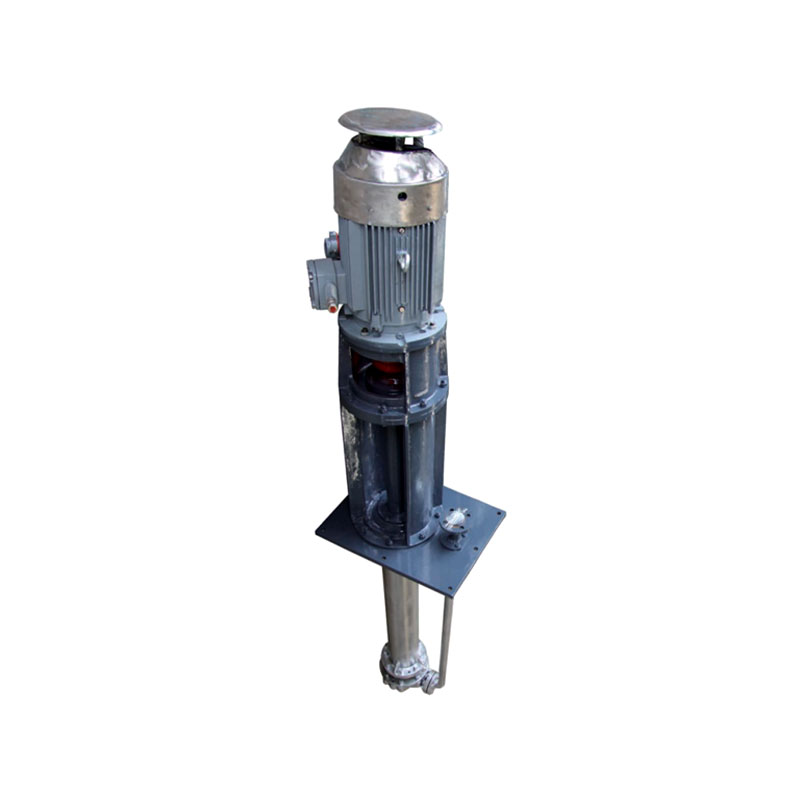

Recommended Products

Products provided by famous enterprises are deeply trusted by users.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP