Through design optimization, improving the energy efficiency of magnetic pumps can not only reduce operating costs, but also reduce environmental impact and promote the sustainable development of water treatment processes.

Fluid Dynamic Optimization Design

Streamlined design of pump body: The design of the internal flow channel of the magnetic pump body directly affects the flow efficiency of the fluid. In traditional pump designs, the fluid's flow path within the pump can create significant resistance, resulting in energy loss. In modern magnetic pump design, the streamlined pump body design effectively reduces fluid resistance and improves energy efficiency by reducing turbulence and vortex effects during fluid flow. Using computational fluid dynamics technology to optimize the design of the pump body can significantly improve the fluid flow state.

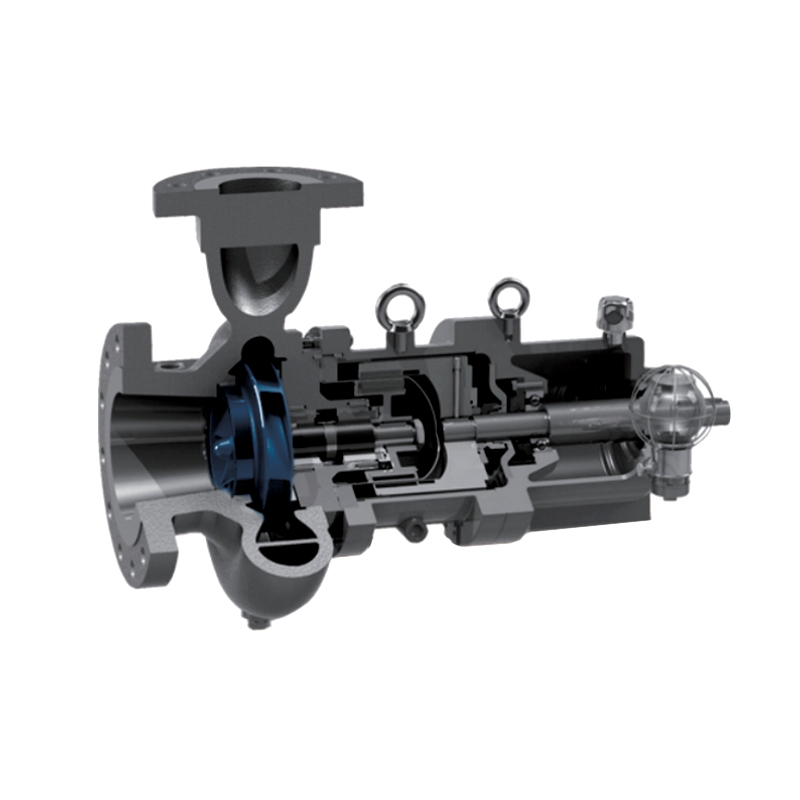

Impeller optimization: The impeller is one of the more critical components in the pump body, and its design is directly related to the energy efficiency of the pump. By optimizing the impeller geometry, blade number, angle, etc., the kinetic energy conversion efficiency of the fluid can be maximized and energy loss reduced.

Improvement of magnetic coupling efficiency

High-efficiency magnetic coupling design: The magnetic pump achieves contactless transmission through magnetic coupling, and its magnetic coupling efficiency is an important factor affecting the energy efficiency of the pump. Traditional magnetic couplers may produce large magnetic losses when transmitting power, affecting overall efficiency. By using high-performance rare earth magnets and optimizing the magnetic circuit design, the magnetic coupling efficiency can be greatly improved and transmission losses can be reduced. For example, using a double-ring or multi-pole magnet structure can enhance the stability and efficiency of magnetic coupling, thereby providing greater output power at the same motor power.

Magnetic resistance design: The magnetic resistance design of the magnetic pump is also the key to improving the magnetic coupling efficiency. By optimizing the layout of magnets and conductive materials in the magnetic circuit and reducing the reluctance loss in the magnetic circuit, the energy transfer efficiency of the magnetic coupling can be improved. This design optimization can be verified through precise calculations and experiments to ensure efficient operation under different working conditions.

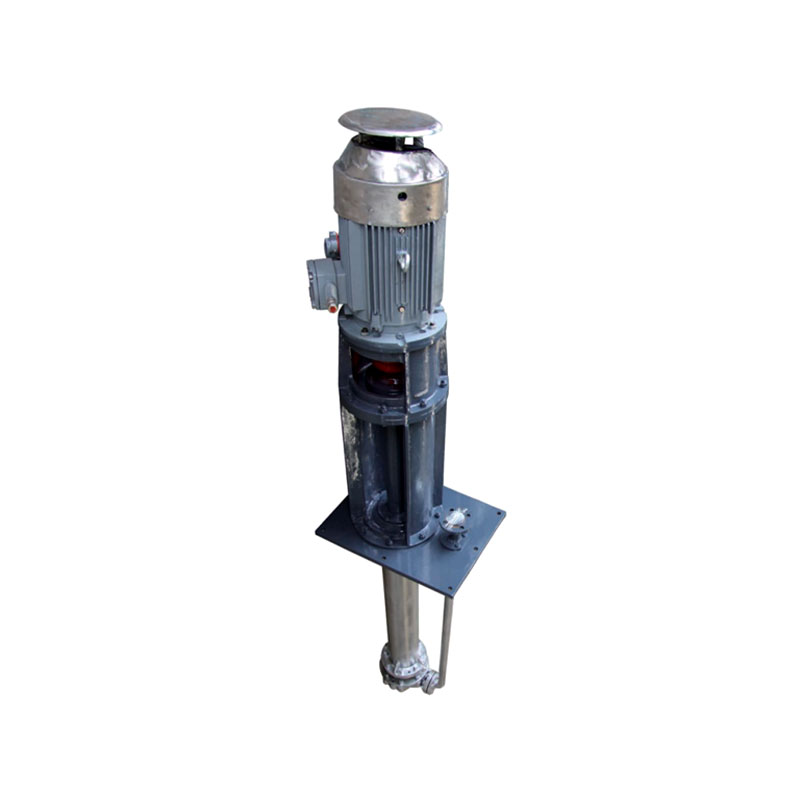

Recommended Products

Products provided by famous enterprises are deeply trusted by users.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP