1. Accumulation and release of kinetic energy

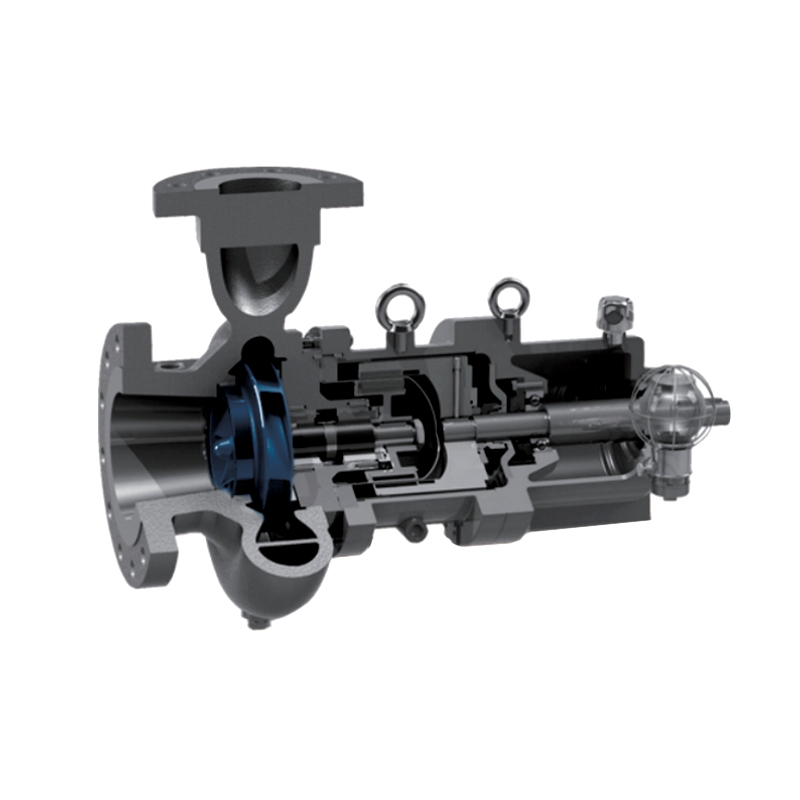

When the Petrochemical Centrifugal Pump starts and the motor drives the impeller to start rotating, a prelude to kinetic energy accumulation slowly opens. The blades of the impeller are like a rotating fan, sucking the liquid in the pump body and driving it to rotate together. As the impeller accelerates, the liquid is thrown to the edge of the impeller under the action of centrifugal force. In this process, the flow rate of the liquid increases sharply, and the kinetic energy continues to accumulate.

2. Change of flow direction and the birth of pressure energy

The accumulation of kinetic energy is not the ultimate goal. Under the ingenious design of the pump casing, the liquid is guided to change the flow direction and flow from the tangential direction of the impeller to the outlet pipe. In this process, the flow rate of the liquid gradually slows down, and the kinetic energy originally stored in the liquid begins to be converted into pressure energy. Pressure energy, this seemingly invisible but powerful form of energy, is the key to the centrifugal pump to achieve fluid pressurization and transportation.

3. Balance and regulation of kinetic energy and pressure energy

During the working process of the centrifugal pump, the conversion of kinetic energy and pressure energy is not achieved overnight, but is in a state of dynamic balance. Factors such as the speed of the impeller, the design of the blades, the shape of the pump casing, and the characteristics of the conveying medium will affect the efficiency and effect of this conversion. Through precise design and adjustment, it can ensure that the centrifugal pump operates under the best working conditions and achieves efficient conversion between kinetic energy and pressure energy.

4. Significance in practical application

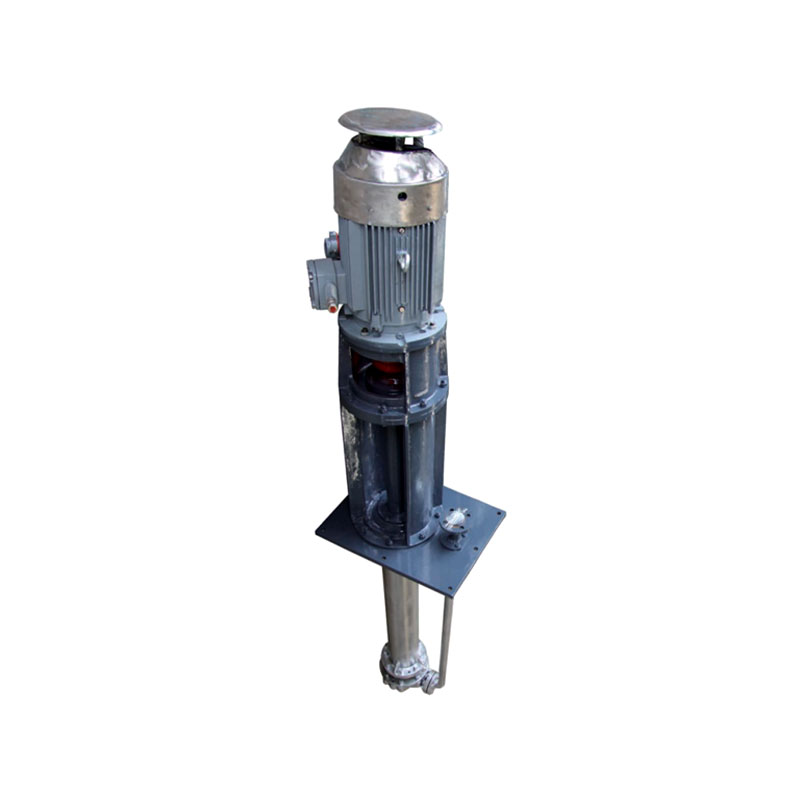

This conversion process of kinetic energy and pressure energy has far-reaching significance in the petrochemical industry. It enables centrifugal pumps to easily cope with various complex conveying tasks. Whether it is high-temperature and high-pressure crude oil transportation or highly corrosive chemical medium treatment, centrifugal pumps can ensure the smooth progress of production. Through reasonable adjustment and optimization, the working efficiency of the centrifugal pump can be further improved, energy consumption and costs can be reduced, and the sustainable development of the enterprise can be contributed.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP