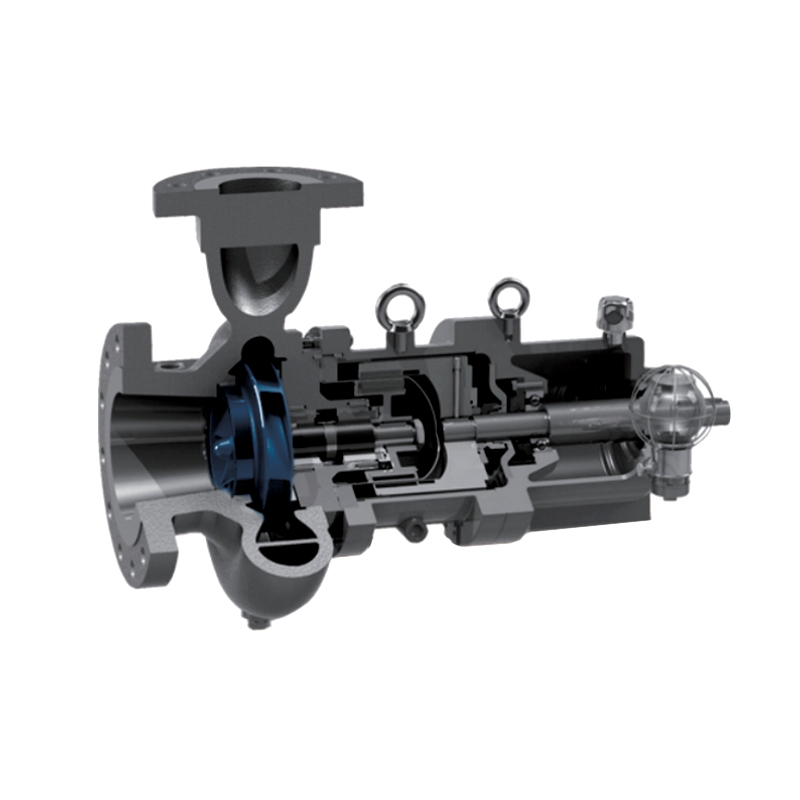

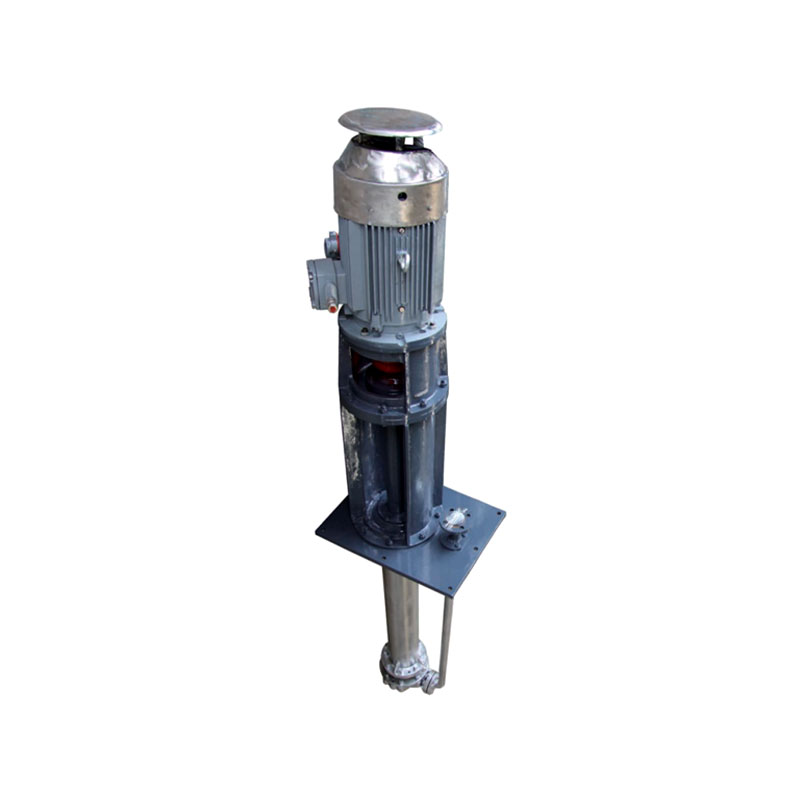

Vertical High-Speed Centrifugal Pump has a wide range of applications in the field of fluid transportation and is one of the indispensable equipment in many industries. For this type of pump, its head is one of the important indicators to evaluate its performance. Vertical High-Speed What factors affect the lift of Speed Centrifugal Pump?

1. The rotation speed of the pump is one of the key factors that affects the lift. According to the working principle of the centrifugal pump, when the liquid rotates with the impeller, it is thrown toward the outer periphery under the action of inertial centrifugal force and obtains energy, thus increasing the static pressure and flow rate of the liquid. . When other conditions remain unchanged, the higher the pump speed, the greater the energy given to the liquid by the impeller, and the higher the lift. Vertical High-Speed Centrifugal Pump achieves high lift by virtue of its high-speed rotating impeller.

2. The diameter of the impeller also has a significant impact on the lift. The lift of the pump is proportional to the square of the diameter of the impeller. The larger the diameter of the impeller, the greater the lift it provides. Vertical High-Speed Centrifugal Pump is usually designed according to specific requirements. It is necessary to select the appropriate impeller diameter to achieve the best lift effect.

3. The physical properties of the liquid are also important factors that affect the head. The density and viscosity of the liquid will affect the performance of the pump. Although the pressure head and flow rate of a centrifugal pump are independent of the density of the liquid, shaft power increases as the density of the liquid increases. Changes in the viscosity of the liquid will directly change its energy loss in the pump, thereby affecting the head. Therefore, when using the Vertical High-Speed Centrifugal Pump, it is necessary to fully consider the physical properties of the liquid being transported to ensure the normal operation and optimal performance of the pump. .

4. The installation and use conditions of the pump will also affect the head. Improper installation, excessive pipeline resistance, wrong motor running direction, etc. may cause the head to decrease. When installing and using the Vertical High-Speed Centrifugal Pump, it is necessary to strictly follow the operating procedures to ensure that the pump is in optimal working condition.

The head of the Vertical High-Speed Centrifugal Pump is affected by many factors, including the pump speed, impeller diameter, physical properties of the liquid, and installation and use conditions. In order to ensure the normal operation and optimal performance of the pump, users need to fully understand these factors. And take appropriate measures to adjust and optimize.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP