Industrial vortex pumps have several significant advantages over traditional impeller pumps when handling media containing solid particles. As a professional manufacturer of Industrial Vortex Pumps, we have accumulated rich experience in this area. Understanding these advantages can help you better choose a suitable pump type to meet specific industrial needs.

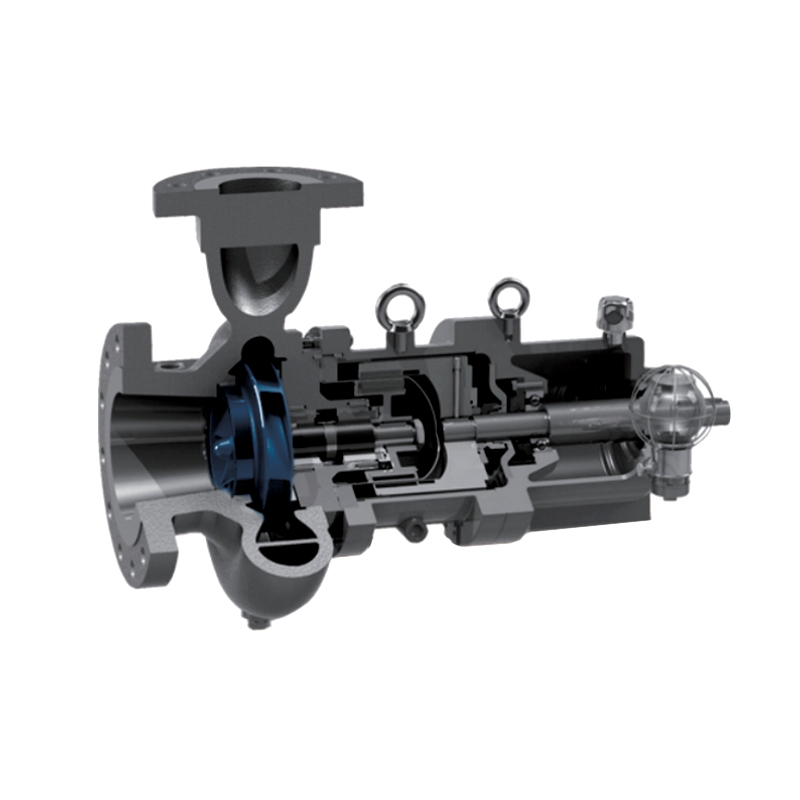

Industrial vortex pumps are designed with a unique structure and are particularly suitable for processing media containing solid particles. Unlike traditional impeller pumps, vortex pumps deliver by forming a rotating fluid vortex inside the pump body. This design can effectively push solid particles without clogging the internal components of the pump. Impeller pumps rely on the rotation of the impeller to push fluid and solid particles, which can easily cause blockage between the impeller and the pump shell, especially when the particles are larger or the concentration is higher.

When solid particles rotate at high speed in the fluid, there is relatively little contact between the inner wall of the vortex pump and the particles, reducing the risk of wear. The impeller and pump casing of traditional impeller pumps will be in direct contact with particles during operation. This direct contact may cause increased wear of the impeller and pump casing, thereby affecting the service life and operating efficiency of the pump.

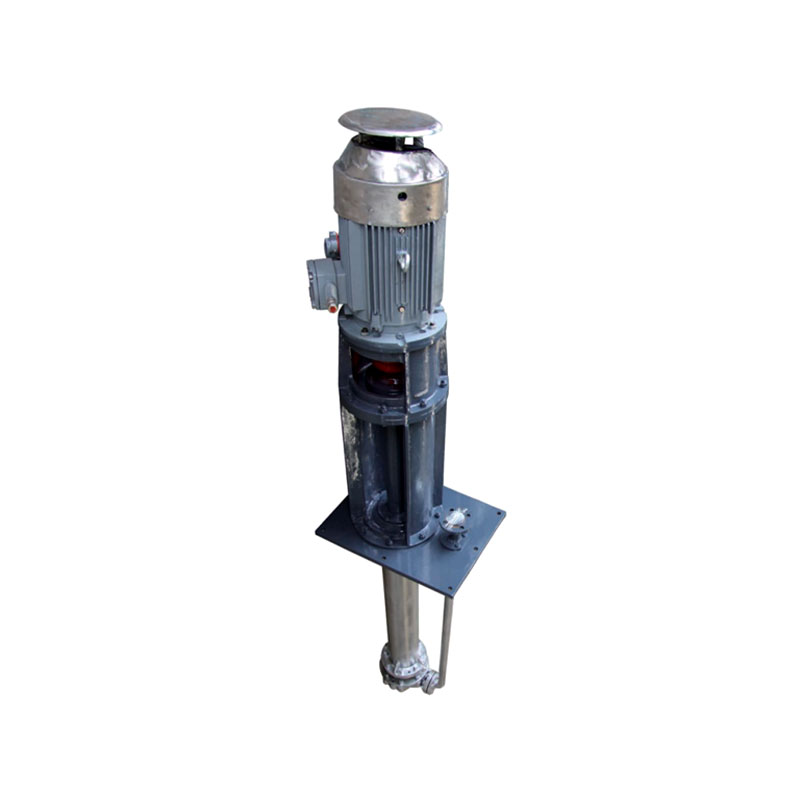

In addition, the vortex pump has a high processing capacity and can effectively handle high-concentration solid particle media. Due to its structural design advantages, the vortex pump can handle media containing larger particles without frequent cleaning and maintenance. This is particularly important in some industrial applications, such as mining and wastewater treatment, where the media often contains high amounts of solid particles.

In terms of energy efficiency, the design of the vortex pump also helps improve the economics of operation. Due to their ability to effectively reduce the wear of solid particles on the pump's internal components, vortex pumps generally have longer operating cycles and lower maintenance costs, thereby reducing overall operating expenses. In comparison, traditional impeller pumps require more frequent maintenance and replacement parts, especially when handling media containing solid particles.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP