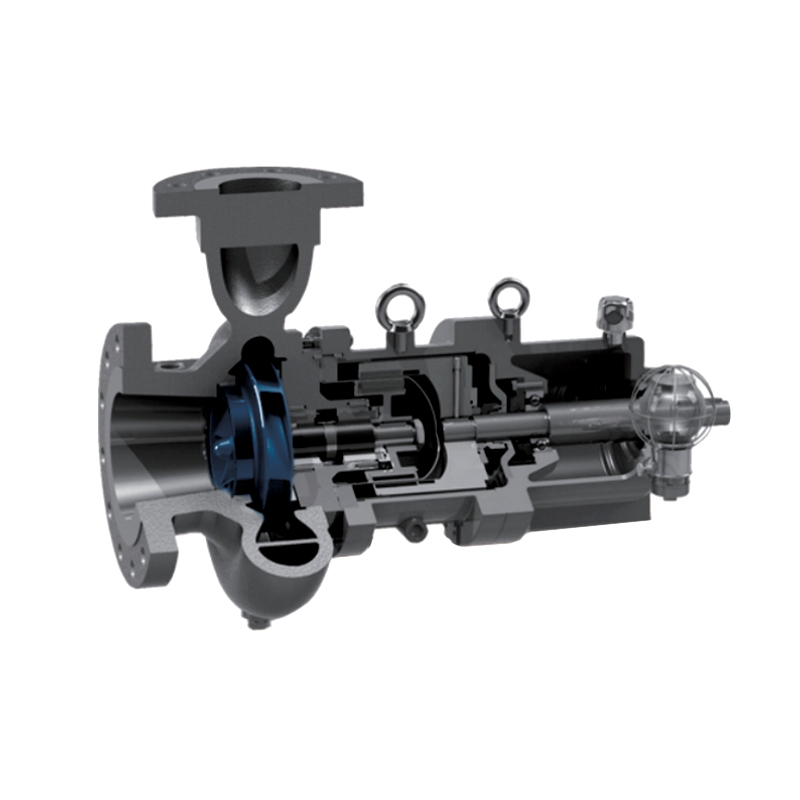

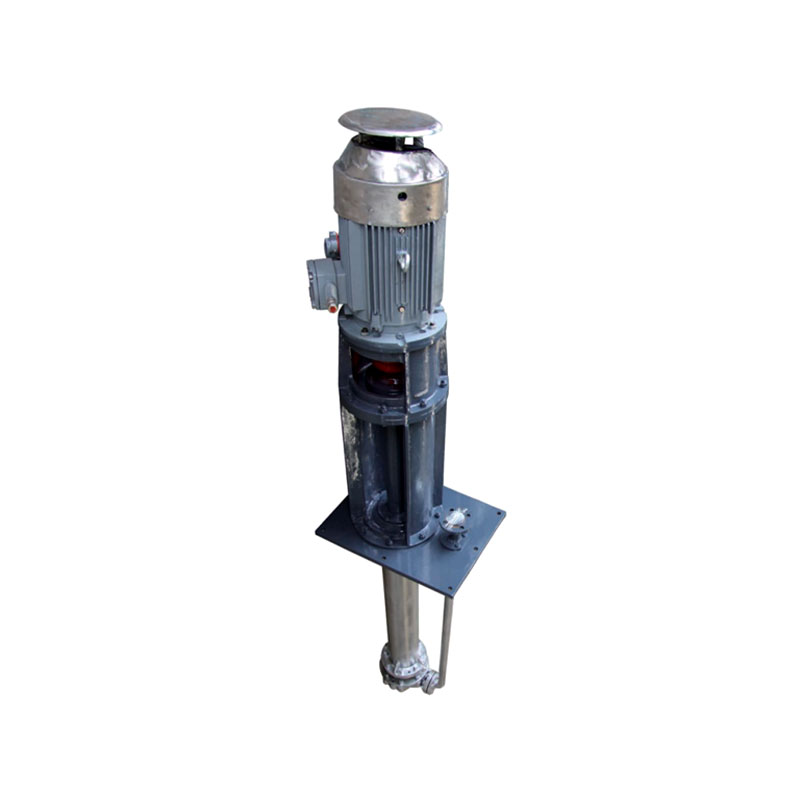

When performing performance tests on industrial magnetic pumps, multiple key parameters need to be considered comprehensively to ensure that the pump performs as designed in actual applications. Flow and head are the most basic test parameters, which measure the volume of liquid delivered by the pump per unit time and the lifting height it can provide, respectively. These parameters can help confirm whether the pump meets the flow and pressure requirements of the actual application. At the same time, testing the pressure and power consumption of the pump is a key step to ensure its energy efficiency and operating economy. High temperature resistance, corrosion resistance, and wear resistance test the stability of the pump under extreme working conditions to ensure that it can operate stably for a long time in high temperature or corrosive media. Noise level and vibration tests help evaluate the comfort and stability of the pump during operation to avoid working environment problems caused by excessive noise or vibration.

Sealing performance is another key test item. The quality of sealing performance determines whether the pump will leak liquid under high pressure and high temperature conditions. The convenience of installation and operation is also an aspect that needs attention to ensure that the pump is convenient and efficient during on-site installation and maintenance. In addition, the stability of the magnetic system, the life of the pump, the energy efficiency rating and the self-priming ability are all crucial to the long-term performance and economy of the pump.

Fluid compatibility, pressure pulsation, vibration and noise monitoring, and performance curve drawing help further understand the performance of the pump under different working conditions. System compatibility testing ensures that the pump can be smoothly integrated into existing equipment. Long-term operation stability testing verifies the reliability and performance durability of the pump in continuous work.

In these tests, we need to use advanced testing equipment to ensure that every industrial magnetic pump can provide excellent performance in actual applications.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP