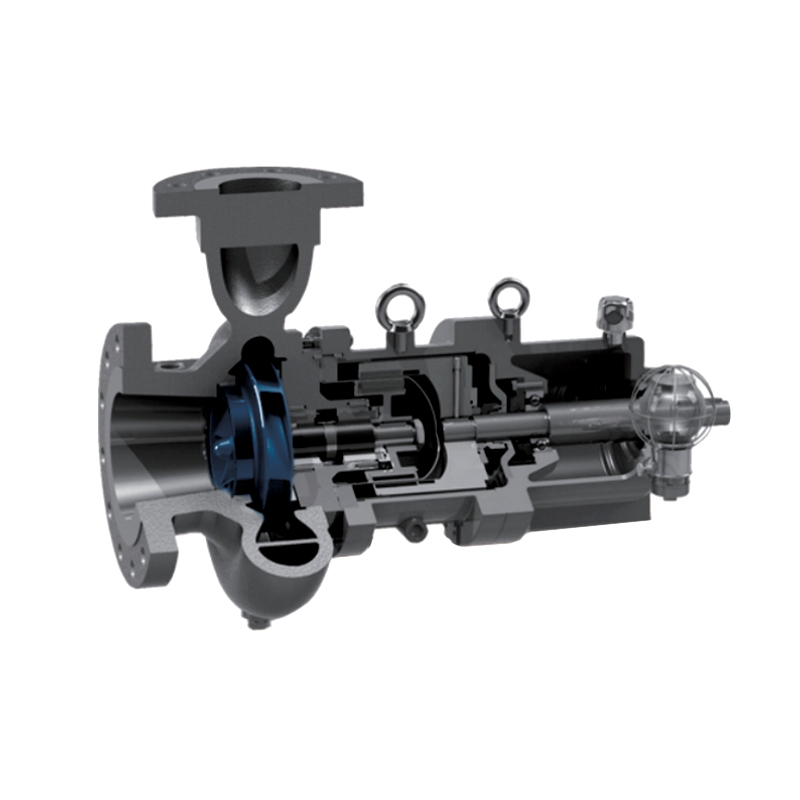

1. High Hydraulic Performance

High hydraulic performance is one of the core advantages of the DCZ series chemical pump. The optimized design of the pump ensures that it can provide efficient liquid delivery under various working conditions. The impeller design of the pump has been carefully optimized to minimize energy loss, thereby improving the liquid delivery efficiency of the entire system. This high efficiency means that the pump can continue to operate with minimal energy consumption even under high pressure or low flow conditions. By reducing energy waste, the DCZ series chemical pump is able to reduce the overall operating costs of the plant, especially during long continuous operation. The pump can meet various industrial needs, including liquid delivery in the fields of chemistry, petroleum, and pharmaceuticals. Enterprises using this pump can enjoy lower electricity consumption, thereby reducing energy consumption and operating costs and enhancing competitiveness. More importantly, the high efficiency of the pump in the liquid delivery process allows chemical plants to better manage production processes and avoid production delays or unstable liquid delivery caused by low pump efficiency.

2. Wide Range of Performance

The DCZ series chemical pump has an adjustable performance range, which makes it perform well in a variety of industrial applications. By adjusting the size of the impeller, the flow and head of the pump can be customized according to specific needs. This high degree of flexibility allows the pump to cope with not only low-flow and high-lift applications, but also high-flow and low-lift working conditions. This adaptability allows the pump to meet the needs of different operating environments, improves the versatility of the equipment, and provides customers with more options, ensuring flexibility for customers in different production tasks. Whether in complex industrial environments such as fertilizer production, sewage treatment or petrochemicals, the DCZ series chemical pumps can provide stable and efficient liquid delivery, avoiding downtime or reduced production efficiency due to inappropriate flow. The performance adjustment of the pump is not limited to flow adjustment, it can also operate stably under different pressure environments, ensuring that the pump can continue to work efficiently no matter how large the pressure fluctuations are during the production process.

3. Improved Cavitation Resistance

Another notable feature of the DCZ series chemical pump is its excellent anti-cavitation performance. Cavitation refers to the formation of bubbles when the internal pressure of the pump drops below the vapor pressure of the liquid. When these bubbles collapse, they generate strong impact force, damage the pump structure, reduce the pump's operating efficiency, and may cause pump failure. The DCZ series chemical pump has greatly improved its anti-cavitation performance and reduced the risk of cavitation by optimizing the design of its impeller and pump casing. Under harsh operating conditions, the pump can effectively avoid cavitation, ensuring that the pump can still operate efficiently under extreme conditions. Its design can maintain stable liquid delivery when pressure fluctuates and liquid flow rate is unstable, which not only extends the service life of the pump, but also reduces the maintenance costs caused by cavitation. The reduction of cavitation means that the pump can operate with higher reliability, avoid excessive equipment wear, reduce equipment downtime, and improve the efficiency and stability of the overall system.

4. Reliability and Reduced Failure Rate

The DCZ series chemical pump is designed to improve its reliability and reduce the failure rate. To achieve this goal, the pump uses a longer pump shaft and cancels the traditional bushing design, which effectively reduces the wear inside the pump and the aging of parts. Compared with traditional designs, the DCZ series chemical pump is more stable during operation, reduces the occurrence of failures caused by wear of parts, and improves the reliability of the entire equipment. The pump casing and internal components are made of corrosion-resistant materials and can withstand harsh working environments such as high temperature, high pressure and highly corrosive liquids, which greatly reduces equipment failures caused by external environmental factors. Reduced failure rates mean that pumps can continue to operate for longer periods of time without frequent downtime for repairs. By reducing the cost of pump repair and replacement, companies can maintain efficient production and ensure that the product production process is not interrupted. This also brings companies a higher return on investment, and long-term use can effectively reduce overall maintenance and replacement costs.

5. Energy-Efficient Design

The DCZ series chemical pumps are designed with energy-saving factors in mind. By optimizing the impeller design and pump body structure, energy loss is effectively reduced. The energy efficiency performance of the pump directly affects the energy consumption and operating costs of the enterprise. For businesses that need to work continuously for long periods of time, every bit of energy savings can significantly reduce electricity bills. During the design process, engineers accurately calculated the water flow resistance and internal friction of the pump to reduce unnecessary energy consumption and improve the energy efficiency of the overall pump system. The efficient operation of the pump can also adjust flow and pressure to match optimal energy consumption levels, maximizing energy usage efficiency under different working conditions. This energy-saving design not only helps reduce electricity costs, but also meets environmental protection requirements, reduces the company's carbon emissions, and is in line with sustainable development goals. After adopting this pump, chemical companies can reduce operating costs and at the same time improve their competitiveness in the market.

6. Simple, Low-Cost Maintenance

DCZ series chemical pumps are designed for easy maintenance and operation, reducing maintenance difficulty and costs. The pump adopts a cassette structure, which makes the installation of single and double seals more precise and does not require professional technicians to perform complicated installation. Maintenance personnel can complete pump inspections and seal replacements in a short time, avoiding long downtime. The design of the pump simplifies the internal structure and reduces unnecessary parts, making the overall system easier to maintain. Due to the simplified structure, the failure rate of the pump is reduced and the frequency of maintenance is reduced, thereby reducing the long-term operating cost of the equipment. The modular design also allows for easy replacement of damaged parts, further reducing repair and replacement costs. For enterprises, this easy-to-maintain design can greatly improve production efficiency, reduce downtime, and reduce the risk of sudden failures during operations. Reduced maintenance costs mean businesses can enjoy higher economic benefits over the long term.

7. Versatility with Multiple Sealing Options

DCZ series chemical pumps offer a variety of sealing options, including single seal, double seal, packing seal and K-type seal, which enable the pump to cope with the delivery needs of various corrosive and toxic chemicals. Different sealing options allow the pump to select the most appropriate sealing method according to different working environments and media properties, thereby ensuring that the pump operation is safer and more reliable. For industries that handle highly corrosive acids or hazardous chemicals, double seals or K-type seals can provide stronger protection against leaks and avoid environmental pollution or safety hazards caused by leaks. In long-term use, seal selection not only improves the durability of the pump, but also reduces the impact of liquid leakage on the production environment. The flexible selection of sealing methods ensures that the pump can still maintain good working condition in various harsh environments, reduces maintenance frequency, and further improves the efficiency and economy of the pump.

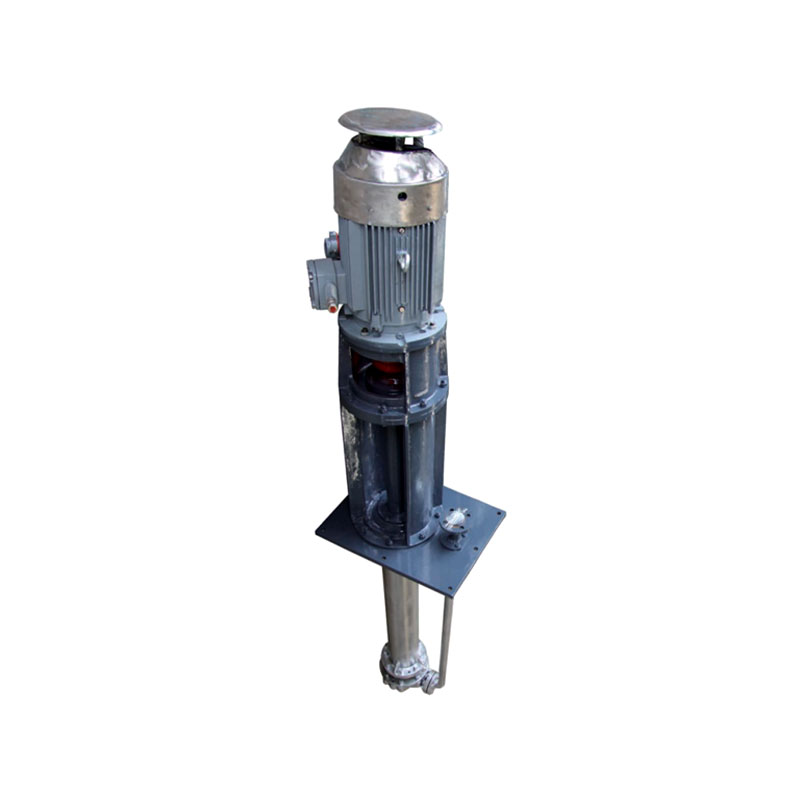

8. Compact and Streamlined Design

The DCZ series chemical pump adopts a compact design, which optimizes the spatial layout of the pump body and reduces unnecessary floor space. This compact design allows the pump to be more easily integrated into existing production systems, avoiding large-scale facility modifications. For factory environments with limited space, the compact design saves valuable work space for enterprises and makes pump installation and maintenance more convenient. Additionally, the compact design reduces transportation and installation costs. Compared with traditional pumps, DCZ series chemical pumps are not only compact in size, but also have a simple internal structure, which reduces interference with other equipment. This design optimization enables the pump to operate stably under various complex working conditions, helping companies make better use of existing space and improve the efficiency of the production process.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP