1. Leak-Proof Design for Enhanced Safety

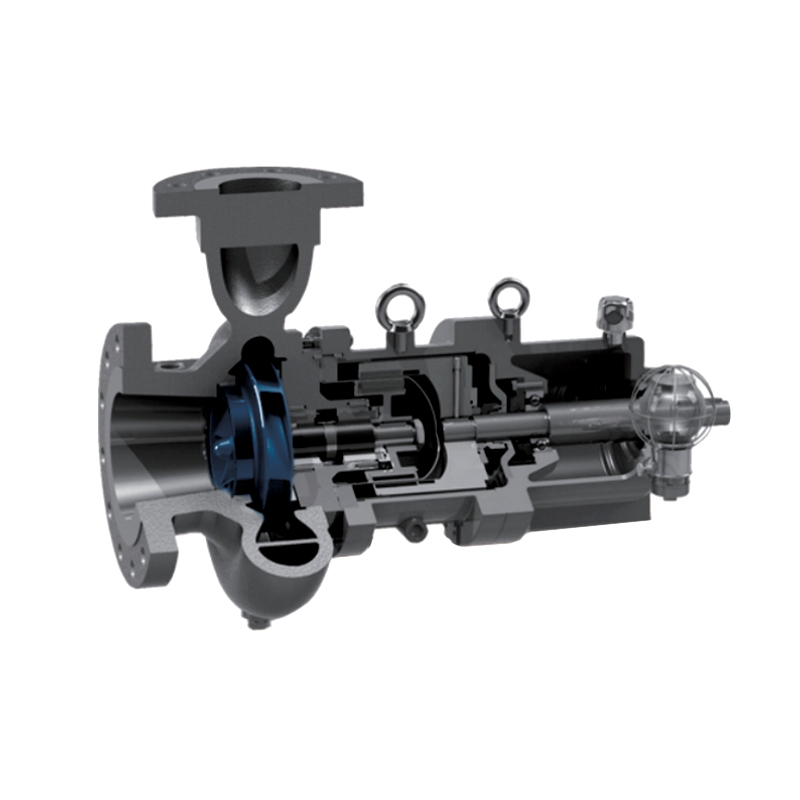

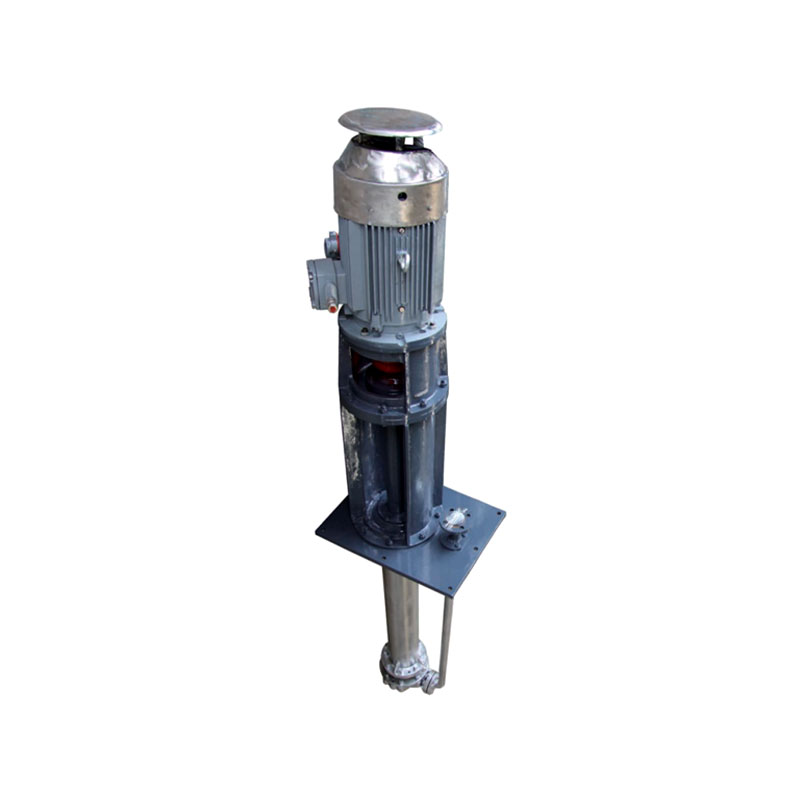

The CQL Series Stainless Steel Magnetic Pump is designed with a static seal mechanism that completely seals the pump’s flow path. This feature is a significant improvement over traditional pumps, which rely on mechanical seals that can wear out over time, leading to leakage. In applications where flammable or volatile liquids are involved, any leakage can be extremely dangerous, posing risks of fires, explosions, or environmental contamination. By ensuring a completely sealed system, the CQL pump mitigates these risks. The use of permanent magnetic coupling eliminates the need for dynamic seals, which are prone to wear, thus enhancing both the longevity and safety of the pump. The leak-proof nature ensures that there are no harmful vapors escaping during the pumping process, a critical factor when handling volatile substances like chemicals, solvents, or oils. This design is especially beneficial in hazardous environments, such as chemical plants, where safety is paramount, and even the smallest leak can lead to catastrophic consequences. By adopting this technology, the pump offers peace of mind to operators, ensuring they are using a reliable system that is safe from leakage, a common problem in traditional pumps.

2. Prevention of Contamination

Contamination is a critical issue in industries that handle sensitive or toxic liquids. In pharmaceutical, food, or chemical processing, even the smallest amount of external contamination can spoil entire batches of products, leading to wasted resources, safety concerns, and regulatory non-compliance. The CQL stainless steel magnetic pump addresses this issue with its fully sealed design. Since there are no contact parts between the pump’s external components and the fluid being transported, the risk of contamination is significantly reduced. Moreover, the use of high-quality, corrosion-resistant stainless steel ensures that the pump’s internal surfaces are not corroded or degraded by the transported liquids. This is particularly important when dealing with aggressive chemicals, volatile solvents, or even pharmaceutical ingredients, where contamination can result in dangerous reactions, ineffective products, or compromised safety. The stainless steel construction prevents any leaching of metals or other materials into the fluid, maintaining the purity of the substances being pumped. The CQL pump guarantees that the integrity of the liquid is maintained throughout the transfer process, meeting the stringent hygiene and quality standards required in these industries.

3. Corrosion Resistance for Long-Term Durability

The CQL Series Stainless Steel Magnetic Pump is built to withstand the harshest conditions without compromising on performance. The pump's body and internal components are constructed from high-strength, corrosion-resistant stainless steel, which is crucial for environments where exposure to corrosive substances is inevitable. In industries such as chemical processing, petroleum refining, or electroplating, pumps often come into contact with highly aggressive fluids that can cause rust, corrosion, or wear. This damage can significantly shorten the lifespan of conventional pumps, leading to frequent repairs and replacements. The CQL pump’s corrosion-resistant construction solves this problem by maintaining the structural integrity of the pump even when exposed to aggressive chemicals or harsh weather conditions. The stainless steel material is resistant to pitting and scaling, common issues when dealing with acidic or alkaline substances. This durability reduces the need for costly maintenance and replacements, providing industries with a cost-effective, long-lasting pumping solution. In sectors that demand continuous operation, such as in refineries or large-scale manufacturing plants, the CQL pump’s durability ensures that the system runs reliably without unexpected downtime.

4. Prevention of Bubbling, Dripping, and Vaporization

In traditional pumps, mechanical seals can sometimes allow for the vaporization of volatile liquids, or cause bubbling or dripping, especially when dealing with substances that evaporate quickly or are under high pressure. These issues can lead to significant operational problems, such as pressure fluctuations, fluid loss, or even dangerous exposure to toxic fumes. The CQL Series Stainless Steel Magnetic Pump, however, eliminates these risks due to its advanced static sealing technology. By fully enclosing the pump’s flow path and removing the potential for dynamic sealing components, the CQL pump prevents the evaporation or vaporization of volatile substances. The elimination of mechanical seals means there is no opportunity for fluid to leak out of the system, thus preventing dripping. This is especially important in industries where precise fluid delivery is necessary, such as in pharmaceuticals or fine chemicals manufacturing, where loss of material could result in quality control issues or production inefficiencies. The ability of the CQL pump to prevent bubbling and dripping also minimizes the risks associated with handling pressurized liquids, providing a safer, more stable pumping solution for flammable or volatile substances.

5. Enhanced Energy Efficiency and Reduced Risk of Fire

Traditional pumps that rely on mechanical seals can generate friction and heat, leading to inefficiencies and an increased risk of fire, especially when handling flammable liquids. The CQL Series Stainless Steel Magnetic Pump addresses these concerns with its unique magnetic drive system, which eliminates the need for traditional seal mechanisms that can cause friction. The absence of moving parts that contact the liquid also reduces the generation of heat, which is crucial when dealing with flammable or volatile substances. The pump operates more efficiently, consuming less energy and minimizing the risk of overheating. This energy efficiency is not only beneficial from a cost perspective, as it reduces electricity usage, but it also enhances safety. In environments where fire or explosion risks are present, minimizing heat generation is critical. The CQL pump's ability to operate coolly and efficiently helps mitigate the risk of sparks or ignition that could otherwise lead to catastrophic accidents, making it a safer option for industries handling flammable liquids.

6. Reliability in Hazardous Environments

In industries that deal with volatile and hazardous materials, reliability is paramount. The CQL stainless steel magnetic pump is specifically designed to operate under extreme conditions without sacrificing performance. Its robust construction and advanced sealing system allow it to withstand high-pressure applications, extreme temperatures, and exposure to harsh chemicals, all without compromising its functionality. This makes it suitable for a wide range of demanding applications, including those found in chemical plants, oil refineries, and pharmaceuticals. In these industries, downtime can be costly and dangerous, and equipment failure can have severe consequences. The CQL magnetic pump’s ability to operate reliably in such environments ensures continuous, efficient fluid transport without the need for frequent repairs or maintenance. The pump’s high operational reliability reduces the likelihood of accidents, such as spills or leaks, making it a critical safety feature in environments where hazardous substances are being pumped.

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP